Ford 7.3-Liter Power Stroke Years To Avoid: Navigating The Pitfalls

Ford 7.3-Liter Power Stroke Years To Avoid: Navigating The Pitfalls

Even one of Ford’s most reliable engines had a few faults.

For decades, the Power Stroke family of diesel engines has done duty in several Ford pickup trucks. The first engine to bear the Power Stroke name was the 7.3-liter turbodiesel V8 introduced in 1994, a revolutionary engine with impressive technologies for the time such as direct injection. While the mill has a generally excellent reputation for reliability, it isn’t without its flaws. Here, we’ll cover the years to avoid for the 7.3-liter Power Stroke engine, as well as the common problems to look out for if you own or plan to buy a pickup with one of these engines. It was fitted to Super Duty Ford trucks like the F-250 and F-350 until it was discontinued due to being unable to meet new regulations.

Manufactured by Navistar International Corporation, the 7.3L diesel V8 is also known as the Navistar T444E. It went into production in 1994 and was initially used in the Ford F-250 and F-350. It also found its way into the Ford E-Series line of full-size vans and the Ford Excursion in the early 2000s.

With a bore and stroke of 4.11 in. by 4.18 in., the 7.3L Power Stroke initially made 210 horsepower and 425 lb-ft of torque. Power and torque steadily increased through the years, culminating in outputs of 275 hp and 525 lb-ft when equipped with a manual transmission.

This engine features electronically controlled, direct injection. Initially, a single turbocharger with a non-wastegate design was used. Early Power Stroke engines had “single shot” HEUI (hydraulically actuated electronic unit injection) fuel injectors. By comparison, more modern common-rail injectors perform five or more injection events per combustion cycle, making them prone to accelerated wear.

A wastegate was added midway through the 1999 model year, along with larger injectors. Around the same time, an air-to-air intercooler was another upgrade. Catalytic converters were only installed late in the engine’s life. It’s partly because this engine could be designed without regard for stringent emission controls, making it simpler, that it is so highly regarded for dependability. For example, the 6.0-liter Power Stroke that replaced this engine had an exhaust gas recirculation system that introduced a whole new range of issues.

Because of its inability to meet California noise regulations, the 7.3L Power Stroke was discontinued early in the 2003 model year and replaced by the 6.0-liter PowerStroke.

In general, this engine has a solid reputation for reliability and can last for over half a million miles if properly maintained. However, there are a few model years that are better to avoid if you want the best chance of getting a used truck with a trouble-free engine.

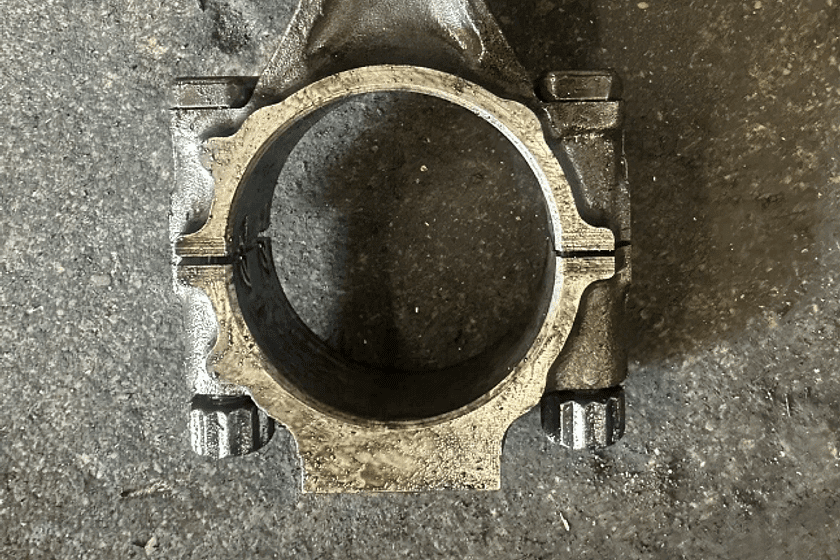

From the 2001 model year, the forged connecting rods that were used for the earlier Power Stroke engines were replaced by less robust powdered metal rods (PMR). The PMRs were fine for unmodified engines, but tuned engines that pushed the output over around 450 hp often resulted in a catastrophic failure of the PMRs. The Power Stroke engine was popular with tuners, with many adding an upgraded turbocharger to boost its rather modest stock outputs.

Further complicating matters is that not all of these more recent Power Strokes had the PMRs. The forged-steel rods were reintroduced for some engines to get rid of the remaining inventory, so it isn’t immediately obvious which ones you’re getting with the more recent PowerStroke-equipped trucks.

Using a boroscope, one can view the serial numbers to figure out which Power Stroke had the forged connecting rods and which had the PMRs. According to 73psd, these are the serial numbers for engines with either forged rods or PMRs:

If you plan on modifying your Power Stroke or are purchasing a modified version, we recommend staying away from the PMRs. 2001-2003 models were also prone to issues with the exhaust, as well as high engine noise related to the split-shot injectors.

While we wouldn’t go so far as to say you should completely ignore these model years of Ford trucks with the Power Stroke engine, there are a few reasons to consider the 1999 model year instead.

Not only are the 1994-1998 engines the oldest, but they also produce the least horsepower of the Power Stroke 7.3-liter family. This can frustrate in daily driving, but shouldn’t be a major issue if all you want is a basic workhorse. In 1998, for the 1999 model year, outputs increased from 210 hp/425 lb-ft to 235 hp/500 lb-ft.

Besides the change to powdered metal rods covered above, there are another few common issues to all of these Power Stroke engines that are worth knowing about, including numerous poor electrical connections.

A worn or failing CPS can cause the vehicle to stall while driving or not start up at all. If the tachometer doesn’t move when cranking, the CPS is likely acting up or in need of replacement. Fortunately, a new one isn’t prohibitively expensive, with an OEM CPS for the Power Stroke listed for $33.95 on ProSource Diesel.

UVCH connectors with these engines are prone to loosening or shorting out, which disrupts contact with the injectors or glow plugs. You can notice this if the engine runs rough or you experience engine-loping, sputtering, or the V8 simply dying completely.

1994 to 1997 Power Stroke engines had two connectors leading into each bank, while later engines had just one connector. It was easier to troubleshoot the specific issue with the harness on the earlier engines. Since the connectors are below the valve cover, it’s wise to replace the valve cover gaskets at the same time.

Once again, this is a reasonably affordable job.

This is a butterfly valve found on the turbocharger, with its main job being to lower the time that the engine needs to return to its normal temperature. This valve can sometimes close and get stuck, leading to hot exhaust air building up in the engine. A jet engine-like noise from the exhaust is one sign that this is happening.

The turbocharger up-pipes of the Power Stroke can leak from various points, but especially at the joints. If this happens, the engine will lose boost and exhaust gas temperatures will rise. A ticking noise through the firewall and lots of black smoke are two symptoms, as is a loss of power.

The IDM is responsible for switching the injectors on and off, based on commands from the Powertrain Control Module (PCM). However, this part can become contaminated with water, leading to failure. A rough idle or the inability to start the truck can be signs of this problem.

This valve can sometimes stick, and since its job is to control the oil pressure in the engine, that’s an issue. A rough-running engine, a sudden stall, or not being able to start the vehicle are all signs of this problem. The engine can often crank but won’t start when this valve malfunctions.

Around two million 7.3-liter Power Stroke turbodiesel engines were made, and for good reason. This unit has a well-earned reputation for reliability, and many of the issues affecting it can be repaired without breaking the bank. It gave Ford a solid alternative to the Cummins B-Series power plant from Dodge and the Duramax V8 from General Motors. Although there are a few more troublesome model years, every version of the Power Stroke has a good chance of racking up over 250,000 miles – and much more than that in some cases – before a major repair is needed.

Responses