WATCH: How Ford F-150 Lightning Is Made At Rouge Electric Vehicle Center

WATCH: How Ford F-150 Lightning Is Made At Rouge Electric Vehicle Center

Here’s a behind-the-scenes look, including how the batteries are produced.

The Ford F-150 Lightning has the bragging rights as the best-selling electric pickup truck in the US, but like any vehicle, life starts at a humble factory, and the YouTube channel Frame is giving us a tour of the Ford Rouge Electric Vehicle Center to see how the model is made.

The facility is Blue Oval’s EV-dedicated production plant in Dearborn, Michigan. F-150 Lightning sales are currently dropping due to significant price increases, but the plant keeps pushing so that Ford is ready when demand picks up again.

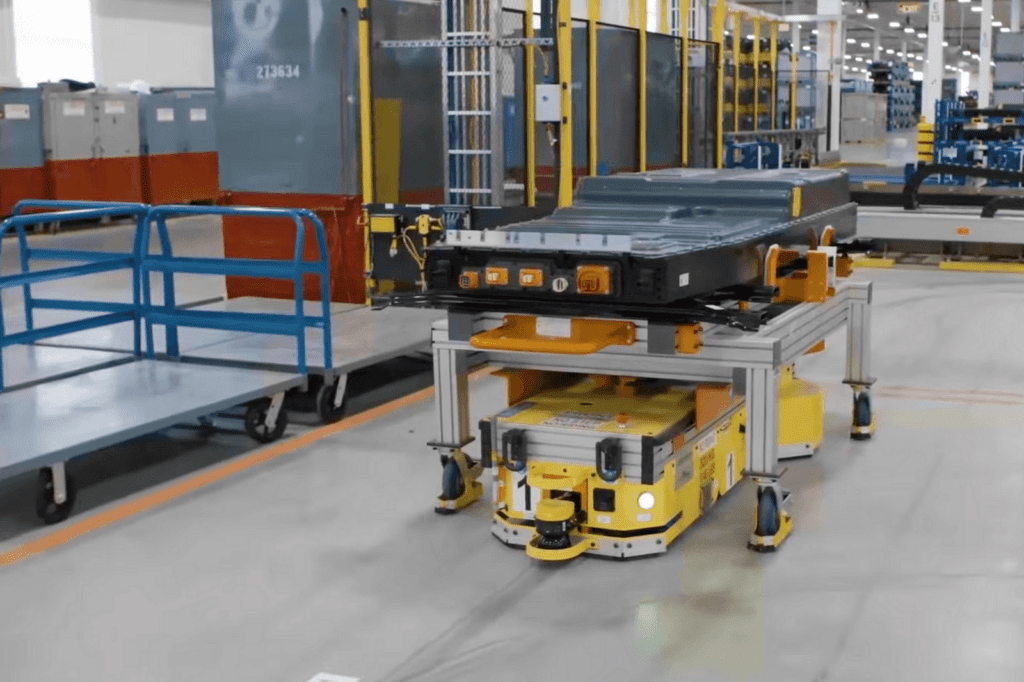

Automated guided vehicles (AGVs) move the assembly parts along the shop floor to different workstations. Lifters and conveyors complement this as some parts cannot be moved by manpower alone.

The workers are tasked to install several components, including the wiring harnesses inside the cabin assembly, secured by fasteners, clips, or adhesive tapes. The headlights, charging port, and mounting bracket are also mounted in place manually, with the badges attached using special adhesive.

Using a specialized jig, the dashboard, which consists of parts like the steering wheel and infotainment screen, is mounted into the cabin. Lifters are deployed to join together the cabin and the truck bed during the frame assembly stage.

Renishaw CMM Machines are used to inspect stator components for surface defects or imperfections. This machine also helps verify geometric dimensioning and tolerancing (GD&T) on the stator components while the rotor is balanced by adding or removing weight. Workers also conduct voltage measurements to ensure the proper voltage supply to the motor’s specifications.

Once the assembly is complete, the units are driven onto Comau Loads Cells to measure their payload capacities. The Ford F-150 Lightning offers a payload capacity of 2,235 pounds, more than the Rivian R1T’s 1,760-lb capacity but less than the Tesla Cybertruck’s 2,500-lb capacity.

The production of the Ford F-150 Lightning should soon be bolstered by a new $3.5 billion battery plant in Marshall, Michigan, initially scheduled for 2026. It aims to lower the prices of Ford EVs like the F-150 Lightning, which should help the model regain good sales momentum. However, the company announced last month that it was reconsidering the future of this plan.

Responses